- Home

- Factory Site

SHARBO has 3 major production bases that covers a total area of about 1,500,000 ft² (140,000 m²) used for the air conditioner parts manufacturing, residential air conditioner production, and commercial air conditioner production, respectively.

Among them, the first and second stage parks have been put into use and have an annual output of more than 2,000,000 sets of products. The third stage park will be started building in 2018, and the estimated annual output can reach up to millions of sets of products.

SHARBO’s injection molding workshop has more than 3,000 sets of plastic molds. As a result, SHARBO can produce different types of air conditioners. Besides, SHARBO has more than 100 automatic plastic injection molding machines whose specifications are from 80t to 1860t. Adopting energy-efficient hydraulic servo system, the automatic plastic injection molding machines are stable, energy-efficient and precision.

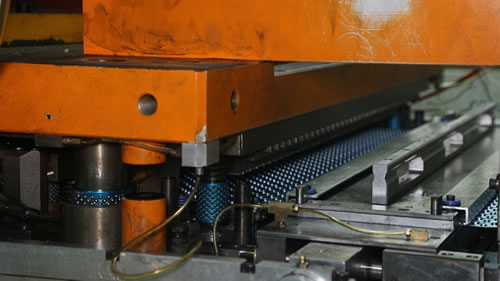

SHARBO’s metalwork workshop has professional metalworking equipment and molds. Among them, there are more than 50 stamping presses. Besides, the metalwork workshop has straightener feeder (3 in 1), spot welding machine, etc.

The annual output of air conditioner outdoor sheet metal parts from SHARBO’s metalwork workshop can reach 2,000,000.

SHARBO’s copper fittings workshop covers an area of more than 32292 sq. ft. (3000 m²). Since most products are produced automatically, the production scale of copper fittings workshop is large and the annual output of air conditioners gas pipes can reach 2,000,000.

SHARBO’s coating workshop has 2 large-scale automatic coating lines. Therefore, the annual output can reach more than 2,000,000 sets of products.

SHARBO’s condensing workshop is a large-scale production center of air conditioner heat exchangers. There are more than 300 employees working in the condensing workshop that has an annual output of 4,000,000 sets of products and provides guarantees for the capacity and quality of both the indoor units and the outdoor units of the air conditioners.

SHARBO has 3 assembly lines for air conditioner indoor unit. Each assembly line is designed to complete assembling one indoor unit in 10 sec, which means that the output of only one assembly line can reach up to 360 indoor units in an hour. And the highest total production capacity of one assembly line is 22,000 indoor units a day.

SHARBO builds a standardized air conditioner testing laboratory that adopts ultra-precision equipment for high/low temperature testing, noise testing, drop testing, electrical safety testing, etc. to ensure the quality and safety of the SHARBO air conditioners.